Unternehmen

Krone Filtertechnik GmbH

Zuverlässiger Schutz für Maschine und Umwelt

Schon seit mehr als 30 Jahren sind wir, Krone Filtertechnik, im Bereich Industriefilter auf dem Markt aktiv und

stehen seither für höchste Produktqualität und kompetenten Service.

Begonnen als Premium-Handelspartner von Mann+Hummel Industriefilter haben wir uns seit 1990

stets weiterentwickelt. Mit dem Vertrieb, der Montage und dem Service von Rußfilter- und SCR-Anlagen

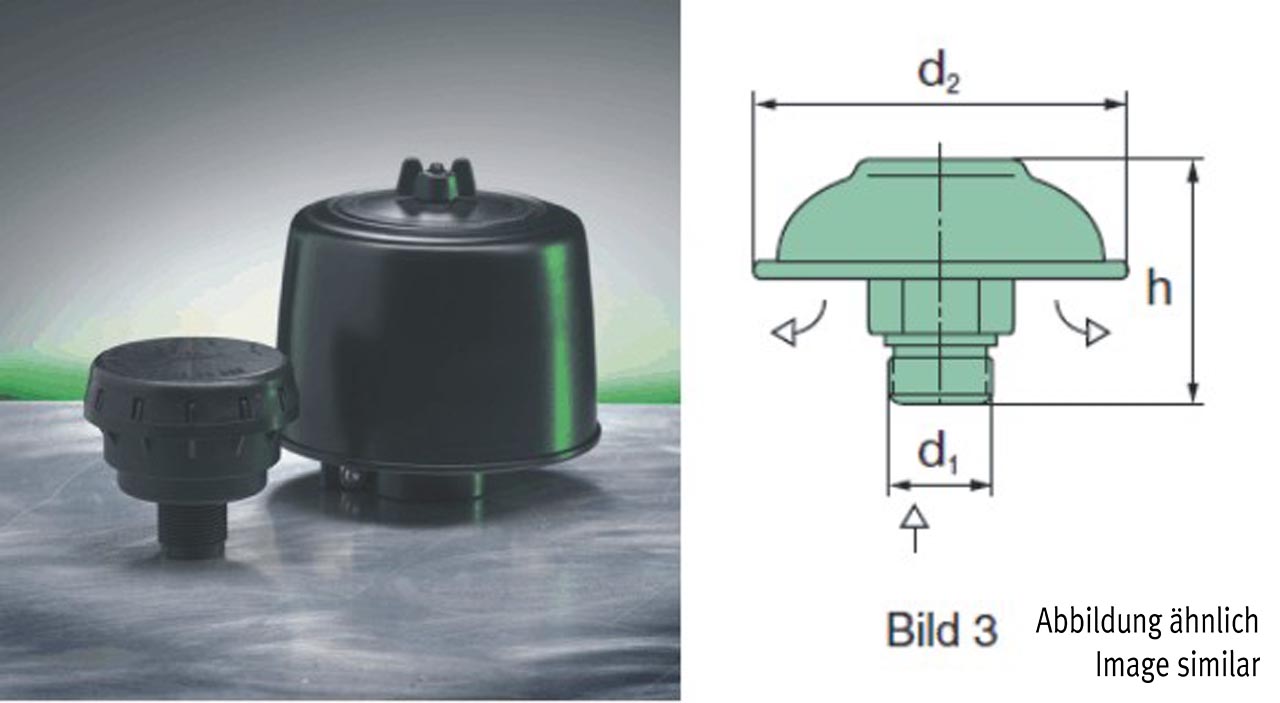

sind wir inzwischen auch zum „Made in Germany“ Hersteller von Vakuumfiltern, Blechluftfiltern,

Ölbadluftfiltern, Spalt- und Plattenspaltfiltern, sowie kompletten Kraftstoff- und Ölfiltern für die Motorenindustrie

geworden.

Unsere Vision ist es, unseren CO2-Fußabdruck in den nächsten Jahren stetig zu verringern, um dem

Klimawandel entgegenzuwirken und unseren Planeten zu erhalten. Dazu achten wir während der gesamten

Wertschöpfungskette auf Nachhaltigkeit. Beginnend beim Produkteinkauf über die Vermeidung von

Kunststoff als Verpackungsmaterial bis hin zur Nutzung von Photovoltaikanlagen und entsprechenden

Speichermodulen, mit denen wir bereits 90% unseres Betriebsstroms selbst erzeugen. Auf dem Weg der

CO2-Reduktion ziehen alle Mitarbeiter an einem Strang und stehen vollkommen hinter unserer Vision.

Kontakt

Team Krone Filtertechnik

Bei offenen Fragen, kontaktieren Sie uns gerne!

Mo-Do: 7:30-16:30 Uhr

Fr: 7:30-13:00 Uhr

Email: Kontaktformular

Tel.: +49 (0) 4202 97 69 0

Krone Produkte

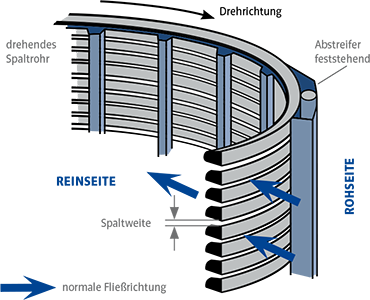

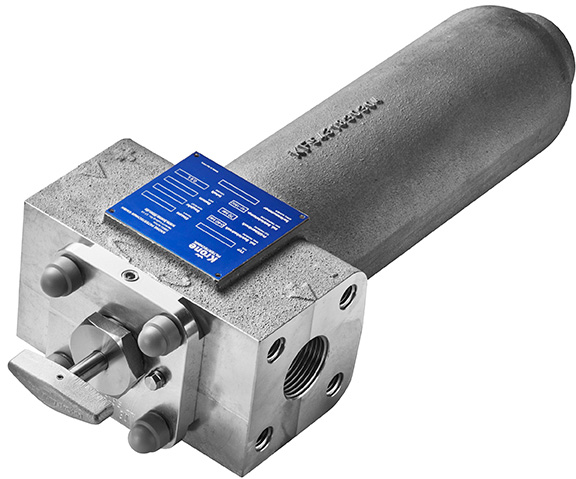

Krone Spaltfilter

Plattenspalt-, Drahtspalt- und Spaltrohrfilter eignen sich zur Filtration stark verschmutzter hoch- und niederviskoser Mdien, wie z.B. Kraftstoff, Schmieröl, Lack, Polyol, Isozyanat, Kühlschmierstoff etc. Sie kommen in nahezu allen Branchen und Bereichen zum Einsatz, z.B. in:

Polyurethan-Herstellung, Spritzguss-Maschinen, Getriebe & Hydraulikpumpen, Kühl- und Schmiermittel, Farben & Lackherstellung, in der Nahrungsmittelindustrie sowie, bei der Reinigung von Wasser und Flüssigkeiten der chemischen Verfahrenstechnik.